|

Know How of Pigment Carbon Black

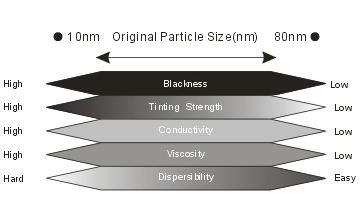

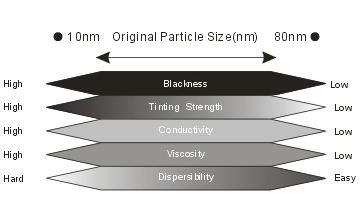

1. Particle Size

The original particle size of pigment carbon black is superposed by slight slices of material. Generally, the original particle size depends largely on technical craft of production. For pigment carbon black processed by the method of furnace, because produce processing methods are adjustable and highly automated, the particle size ranges change is largest, from 10nm to 80nm. Generally speaking, the average size and the distribution of original particles fundamentally decide the performance of pigment carbon black, especially the blackness and tinting strength.

|

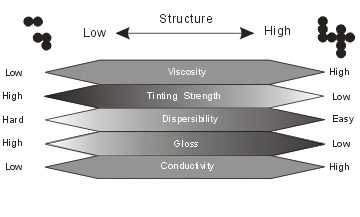

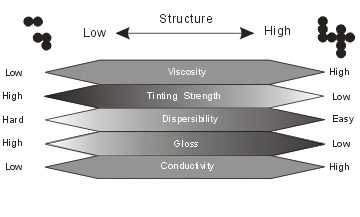

2. Structure

The original particle of pigment carbon black does not exist by nanoscale and single. They form congeries and agglomerates through physical process. The conglomerating size of furnace-processed pigment carbon black can be adjusted by changing of the technical craft, while contact-processed blacks for its open degree of concentration process if difficult to control. Conglomeration of original particles of carbon black is used to being called ‘structure’. Pigment carbon black with high conglomeration is called high structure, while with low conglomeration is called low structure.

|

|

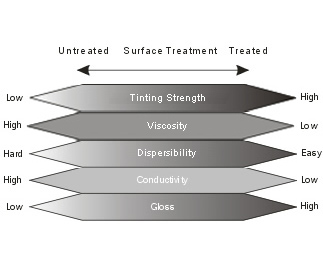

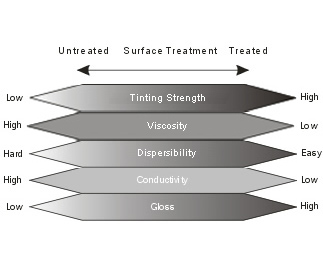

3. Surface Activity

Carbon black consists mainly of carbon elements with carbon content about 90% ~ 99%. Carbon black also contains a small amount of hydrogen, oxygen, nitrogen, and sulfur elements. Here mentioned surface activity, for acid carbon black, is referring to the amount of oxygen surface groups generated on surface of carbon black particles. These acid surface groups are mainly for carboxylic acid, phenolic group, benzoquinonyl, lactone, etc. For alkaline carbon black is referring to the alkaline oxidations on surface of carbon black, which will affect the physical and chemical properties of carbon black, such as wetting dispersion, catalytic activity and electrochemical performance.

|

|

The properties of Pigment Carbon Black

1. Tinting Strength

Also can be called shading strength. Tinting strength means the performance of colour strength shown in the form of percentage, which is evaluated by the reflection rate of gray paste that mixture of the carbon black, titanium dioxide (or other white pigment like zinc oxide) and linseed stand oil, with reference to industry standard.

All results are worked out under the testing standard of ASTM D-3849 or GB/T 7050-2003.

2. Surface Area:

Surface area of carbon black indicates the total surface area of carbon black particles per unit of mass or bulk volume, with units of m2/g. Surface area, similar as particle size, shows performance characteristics of carbon black. Generally speaking, the carbon black with smooth surface, its surface area and particle size are contrary to each other, which is the smaller the particle size, the bigger the surface area, and vice versa. So if we assume that carbon black particle is spherical, we could calculate specific surface area if we know its particle size.

Surface area of carbon black includes exterior specific surface area (smooth specific surface area), inner specific surface area (inner pore specific surface area) and total specific surface area. Total specific surface area is calculated by adding exterior and inner specific surface area together. There are many measurements for specific surface area, of which the most commonly used are BET nitrogen adsorption method, iodine adsorption method, CTAB adsorption method (giant molecule adsorption method), t value method and electron microscopy etc.

3. DBP Uptake Value

The carbon black structure can be measured by DBP (DiButyl Phthalate) absorption. Usually, according to experience, DBP absorption of low structure should be less than 70ml per 100g of pigment carbon black. However, for high structure pigment carbon black, the DBP absorption per 100g of pigment carbon black should be more than 110ml. Middle structure carbon black is between the above two on DBP. It’s structure that gives substantial influence on performance of pigment carbon black while application.

(The results of DBP absorption of pigment carbon black are worked out under the testing standard of ASTM D-2414 or GB/T 7046-2003.)

4. PH Value:

The pH value is related to the amount of surface chemical functional group. Surface of furnace-processed pigment carbon black has less organic functional group and exiguous water soluble salt, which makes majority of pigment carbon black show neutral or alkali in pH value. In order to improve the viscosity, stability and fluidity, some types of pigment carbon black are improved on the quantity of organic functional group via surface treatment. Hence pH value of those types shows acid.

(The pH value is measured refer to GB/T 7045.)

|